VIAL FILLER, Sterile micro volume

Automated high precision filling of vial batches in sterile conditions

Introduction

Are you looking for a solution for precise and reliable small volume vial filling for your production line that only requires attention of the operators twice a day? Dealing with volumes between 100 µl and 2 ml, need ful data tracking? This filler unit may offer a quick solution to your needs.

Automated reagent filler

Nucomat has engineered a compact and flexible automated platform for unattended vial dispensing provided inside a safety enclosure. This unit is ready for installation and just requires your input settings and a user training to get you going with accurately filling batches of research grade reagents and kit solutions in screwcap vials.

Your benefits

- Throughput: 80 vials/h, up to 1600 vials/day.

- Traceable and repeatable hands-off 24/7 reliable operation.

- Stand-alone workflow with data integration possibility.

- Compact 1.0 x 2.3 m cabinet,

2.4m high, ready for installation,

0.5 x 0.5 m floor mounted cooler.

Dispenser Features

- Dispensing with 1ml high precision Hamilton syringe, accuracy 10µl, precision 0.5µl.

- Gravimetric control of dispensed mass at 1 mg resolution.

- Sterile: HEPA filtered laminar flow.

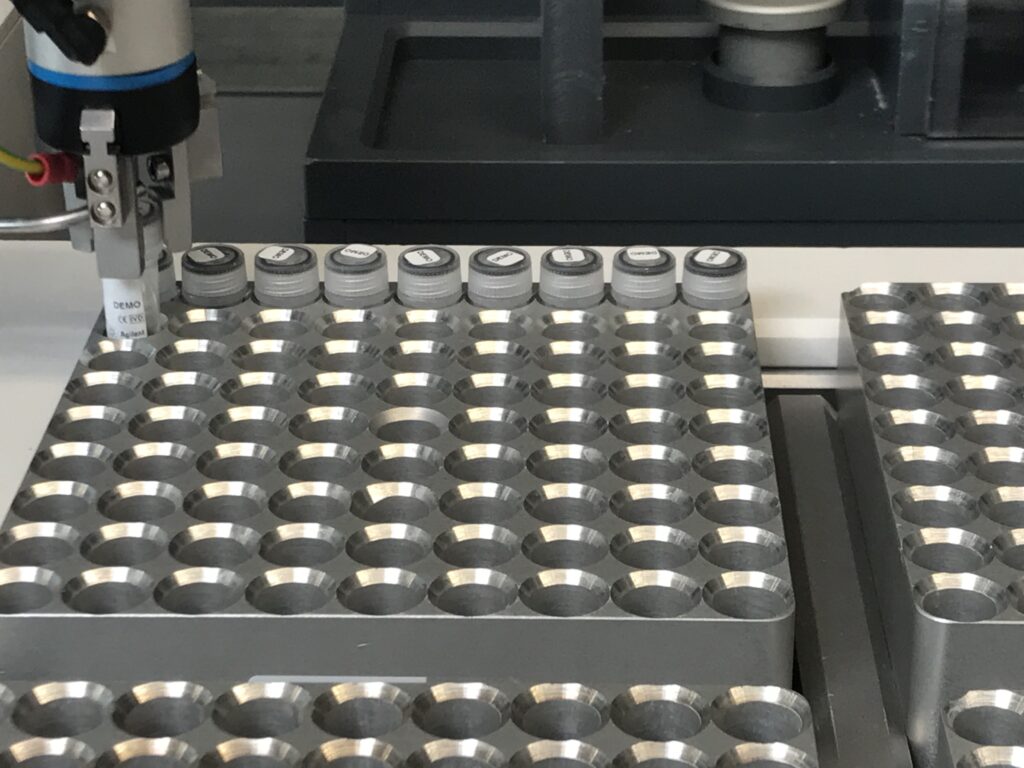

- Capacity: up to 810 vials per load (10 output racks of 9×9 vials)

- Cooling: Output vial rack and reagent source cooling to +2°C.

- Dual Labeling, on vial and cap:

- Vial label: Vial Id, manufacturer logo, volume, lot nr., expiry date, storage temperature, etc.

- Cap label with vial Id.

- Content and layout can be configured to meet your requirements.

- Input flasks 15ml, 50ml, 250ml and 500ml, Output vials: Nalgene screw cap 0.5 ml to 2 ml.

- Space saving overhead Cartesian robotics with Reproducible operation, built to last.

- Bulk vial feeder with funnel load from front panel.

- Operator safety: Safety lock, with interrupt on unauthorized opening.

- Minimal energy requirement: 120-230V 10Amp, Compressed air 4-6 bar <64L/min, LAN connection.

Central web based software

- ROBIN: Nucomat’s proprietary real-time event-driven scheduling software for process control

- Web interface for local and remote operation:

- run samples

- oversee the processes

- edit protocol parameters

- error handling, smart retry, run recovery.

- Sample Database

- sample tracking with gravimetric dispense control logging

- event logging

- data import, export and reporting, integrated data managementcompatible.

Vial formats

Vial feeder

Cooled output rack

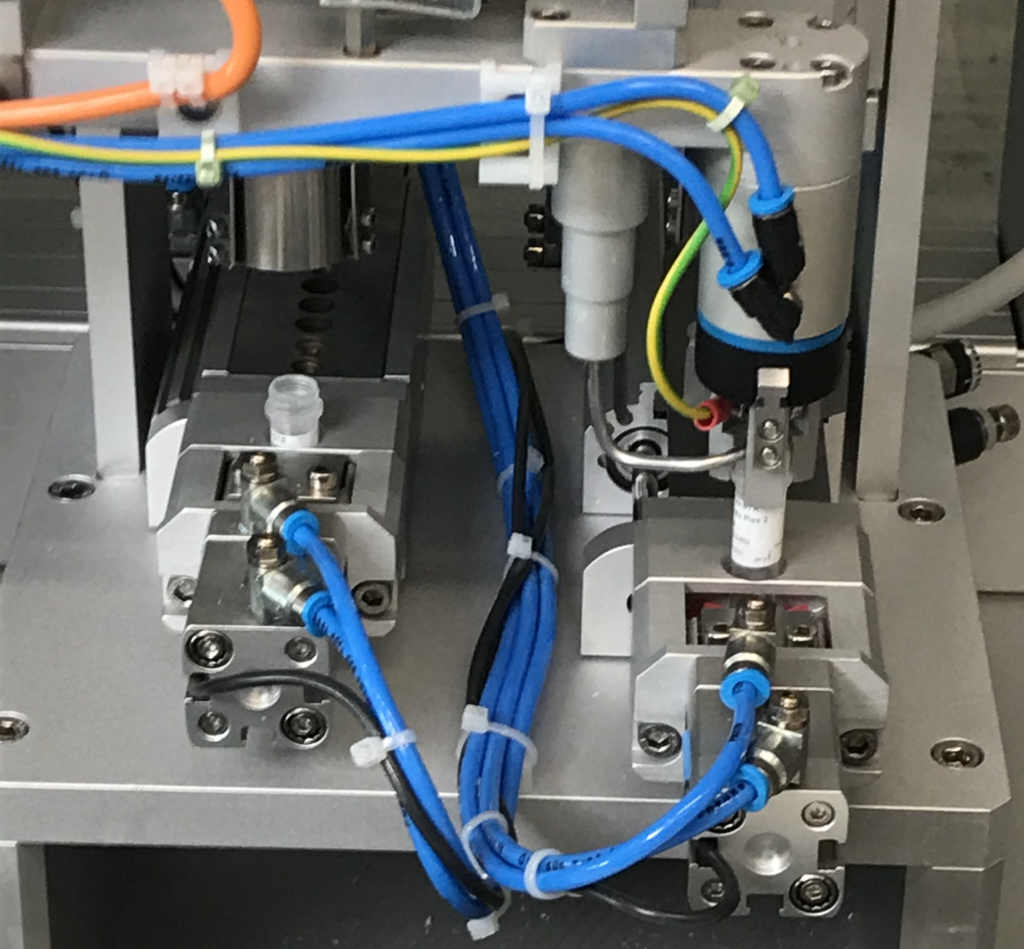

Dual decapper

Balance controlled dispenser